New devices

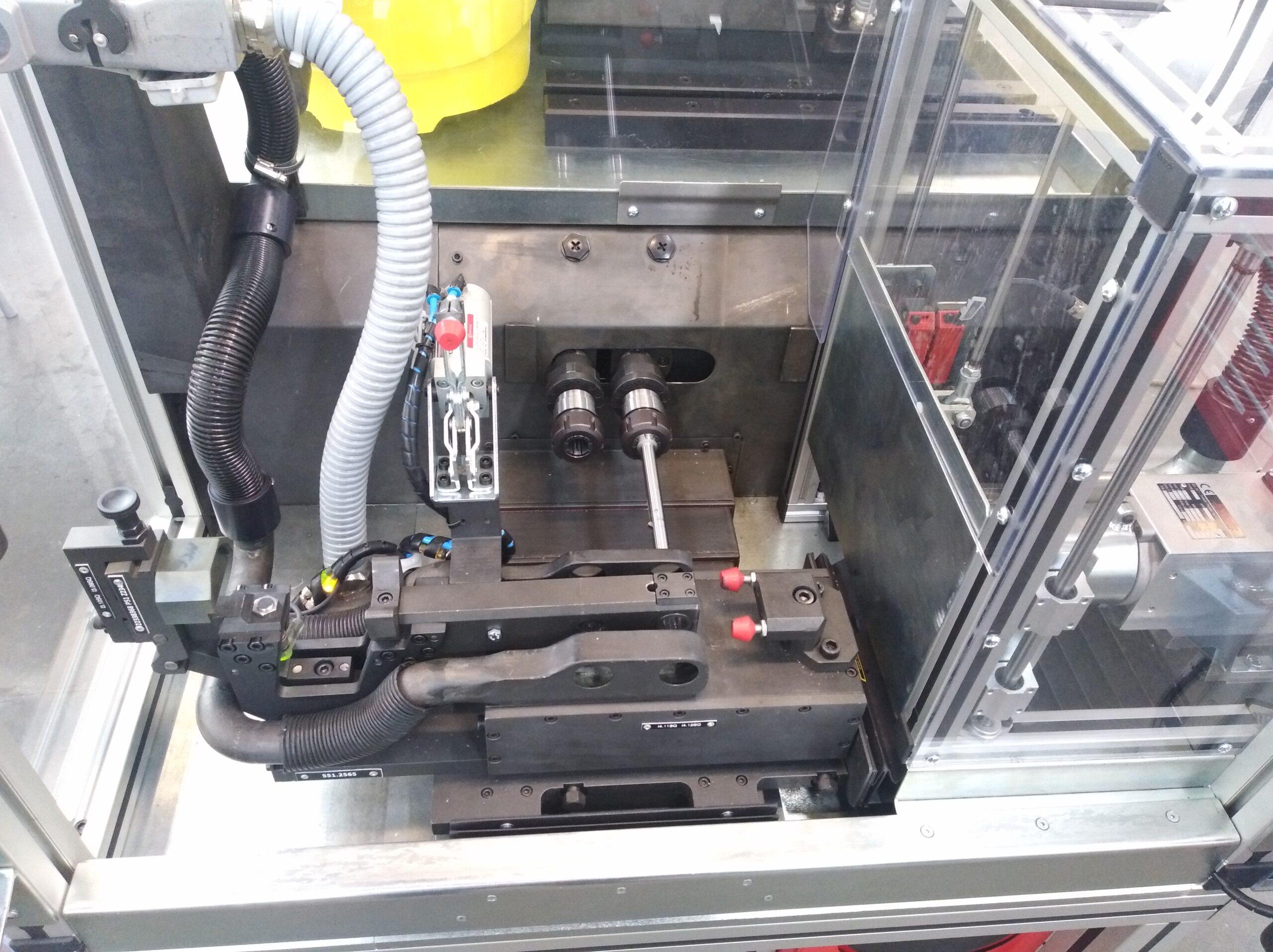

A machine for chamfering holes and brushing the end of the clamp

Device for deburring steering gear wheels

Machine for washing the rack bars

Device for narrowing pipes. Working pressure: 400 [kN].

The device was built based on BOSCH aluminum profiles.

The main units of the device are:

– working frame,

– ejector and spindle rotation system,

-device for a spreading

– hydraulic aggregate,

– interchangeable equimpent.

Device for narrowing pipes. Working pressure: 250 [kN].

The device was built based on BOSCH aluminum profiles.

The main units of the device are:

– working frame,

– ejector and spindle rotation system,

– height adjustment system,

– vice clamp system,

device for a spreading

– locator punching system

– hydraulic aggregate,

– interchangeable equipment

Device for pressing the steel sleeve into the shock absorber’s ear.

The device is equipped with replaceable equimpent (coded).

A bar code reader (3D) has been installed on the device.

The force and pressing path are monitored.

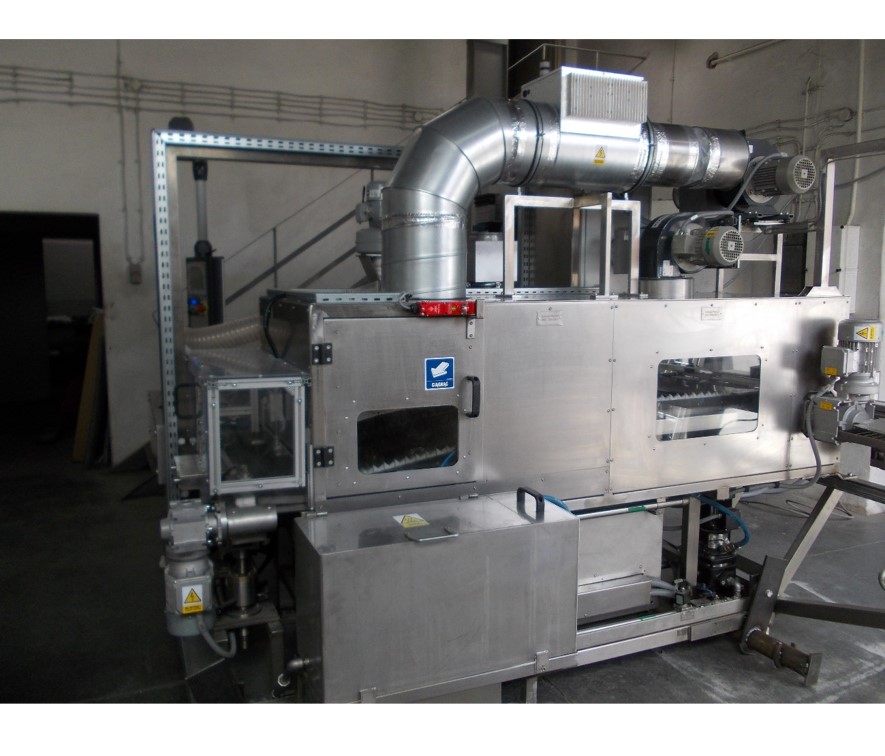

Cylinder cleaning device after rounding.

The device is designed to clean the cylinder (inside and outside)

after the hot closing operation. The plastically deformed zone

is cleaned and changed from the influence of temperature.

Device for pressing the plate onto the shock absorber cylinder.

The device is intended for pressing the plate onto the cylinder.

The device has a variable value of force needed to complete the process.

Incompatible details are directed to the defective products separator.

The device has a variable height position of the main beam and stroke

of the working cylinder. Automatic movement of the main beam

to position and setting of the cylinder stroke according to the selected

work program. The device can also work on the principle of a hydraulic

press (e.g. pressing). Strength and work path are controlled.

Device for the welded joint test.

The device is designed to test the plate-cylinder weld connection.

It has adjustable test strength value. During the test, the length

of the welded component is additionally analyzed. Incompatible

details are directed to the defective products separator.

Weld test device.

The device is designed to test the plate-cylinder weld connection.

The device has a variable value of test force, automatically set after

selecting the work program. During the test, the length of the welded

component is additionally analyzed. Incompatible details are directed

to the defective products separator. The device can also work on th

principle of a hydraulic press (e.g. pressing).

Bar feeder. (erector)

The device is intended for feeding piston rods to a horizontal

conveyor, checking the presence of thread and correct orientation

of the threaded end of the piston rod in relation to the feeding

direction. In the absence of a thread at the tip, the piston rods

are directed to the gap separator.